Woody Associates, Inc.

Providing automatic decorating equipment to the Bakery and confectionery industry for over 60 years. As a staple in modern production, the Woody Stringer has the ability to produce zigzag, curved and looped design patterns to bakery and confectionery items in a fully automated system.

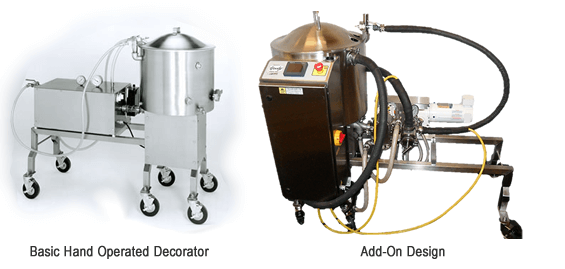

Each Stringer is custom designed to meet the individual needs of the user. We will utilize factors such as line speed, width and the desired decoration pattern to produce a machine that will exceed expectations and withstand the test of time. The Woody Stringer can be designed to decorate on a conveyor, over a gap or fitted in an enrober.

Many machines in use today are more than 40 years old. In 1954 Woody Associates was founded as George D. Woody Associates, a consulting firm specializing in production issues the confectionery and textile industries faced as they related to automation. Through his experiences as a consultant, George Woody recognized there was a need for automatic decorating machinery.

First produced out of his Atlanta home in 1956, the Stringer proved to be the solution. This new automatic decorating device was capable of adding zigzag decorations in an array of thicknesses on top of confectionery goods.

Bakery Stringers

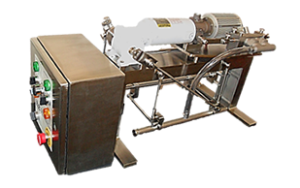

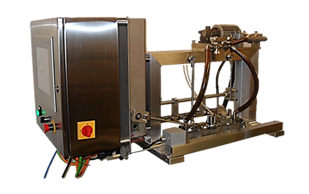

Designed with continuous operation in mind, the bakery model of the Woody Stringer is constructed to withstand hours upon hours of continuous service without the need to halt operations.

The bakery model differs from the confectionery model based on the typical inclusion of Heavy-Duty Construction. The Heavy-Duty Construction includes heavier rods, a larger frame and a stronger drive motor. Higher capacity product areas improve performance during high-level production sessions.

As with all of our Woody Stringers, the basic model of this machine comes equipped to produce zigzag designs. Simple adjustments permit the user to make fast or slow, wide or narrow, thick or thin decorations. Each Stringer is equipped with our patented motor driven strainer, which cleans the chocolate before it reaches the nozzle tube ensuring consistent operation all day long.

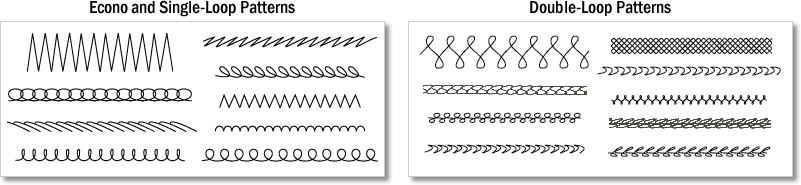

Design upgrades of this Stringer can include the Single-Loop Attachment, allowing users to create loops, circles, slanted ovals and slanted zigzags. Also available is the Double-Loop Attachment, which allows an increased selection of decorative patterns including a figure eight (8) design.

The Bakery Stringer can also be designed to make random patterns to simulate hand decorating, cross-hatching patterns and more.

Bakery StringerQuick Facts

- Available in 120V/230V single-phase or 240V/480V three-phase operation

- Fractional horsepower motors for energy efficiency

- Available with 56C face motor

- Simple installation and cleaning procedures

Additional Options

- Single-Loop Attachment

- Double-Loop Attachment

- Nozzle Heater

- Heated Enclosure

- Purging Nozzle Tube

- Washdown Construction

Finance available on orders over £1,000

Start-up Businesses

Finance fromMedium Businesses

Finance fromLarge Businesses

Finance fromVantage House can help with your purchase through various payment options using Time Finance.

For an indication of deposit and monthly payment structure please click the Get a Quote button or phone our friendly team.

Please note other lenders are available.