Woody Associates, Inc.

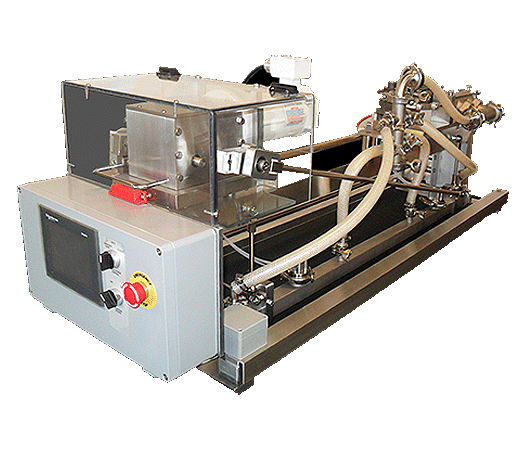

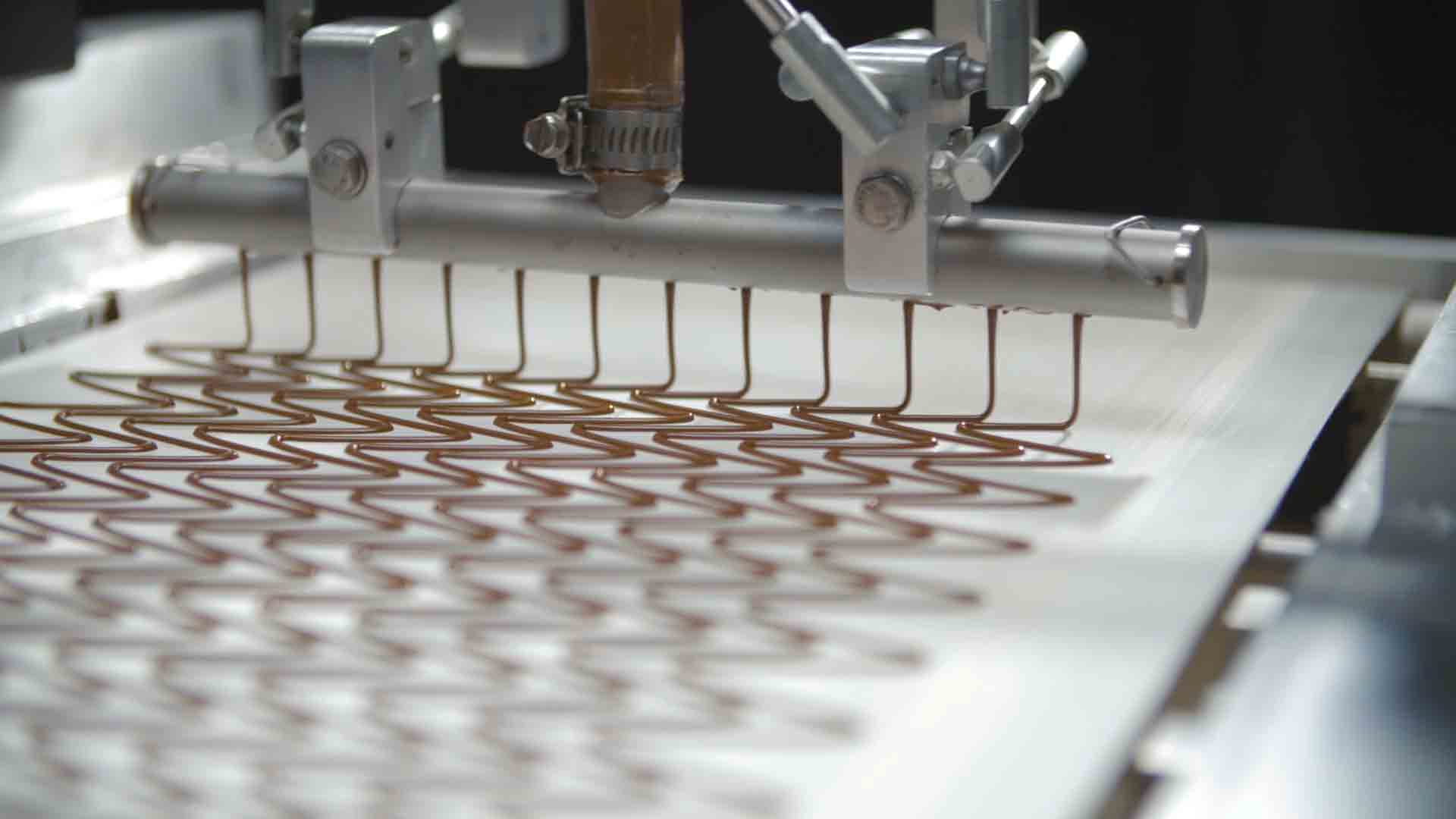

Providing automatic decorating equipment to the Bakery and confectionery industry for over 60 years. As a staple in modern production, the Woody Stringer has the ability to produce zigzag, curved and looped design patterns to bakery and confectionery items in a fully automated system.

Each Stringer is custom designed to meet the individual needs of the user. We will utilize factors such as line speed, width and the desired decoration pattern to produce a machine that will exceed expectations and withstand the test of time. The Woody Stringer can be designed to decorate on a conveyor, over a gap or fitted in an enrober.

Many machines in use today are more than 40 years old. In 1954 Woody Associates was founded as George D. Woody Associates, a consulting firm specializing in production issues the confectionery and textile industries faced as they related to automation. Through his experiences as a consultant, George Woody recognized there was a need for automatic decorating machinery.

First produced out of his Atlanta home in 1956, the Stringer proved to be the solution. This new automatic decorating device was capable of adding zigzag decorations in an array of thicknesses on top of confectionery goods.

Which Woody Stringer is best for you?

Vantage House

Delighted to be appointed sole agents for Woody Associates. Inc in the UK & Ireland.

As time progressed so did the abilities of the Stringer. During the 1960’s new capabilities were added to the Stringer in the form of the Single-Loop Attachment. This upgrade allows the stringer to create circles, ovals and slanted zigzags. In 1974, the Double-Loop Attachment was born, allowing users to create figure-eight and cross hatching design patterns.

Due to an increase in demand for the Woody Stringer, George Woody moved the business to York, Pa. for manufacturing in 1974. York’s close proximity to major industry locations such as Hershey, Pa., Baltimore, Philadelphia, New York and Washington, D.C. made it a prominent choice for relocation.

Woody Associates was awarded the Presidents’ E Award in 1981. The award is given to businesses that show significant increases in exports over a three year period.

Harry A. Reinke, III took over as the president of Woody Associates, Inc. in 2002. In 2005 he relocated the business to a larger manufacturing facility at their current location.

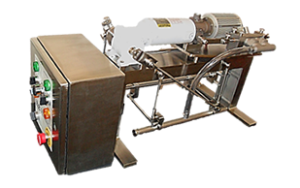

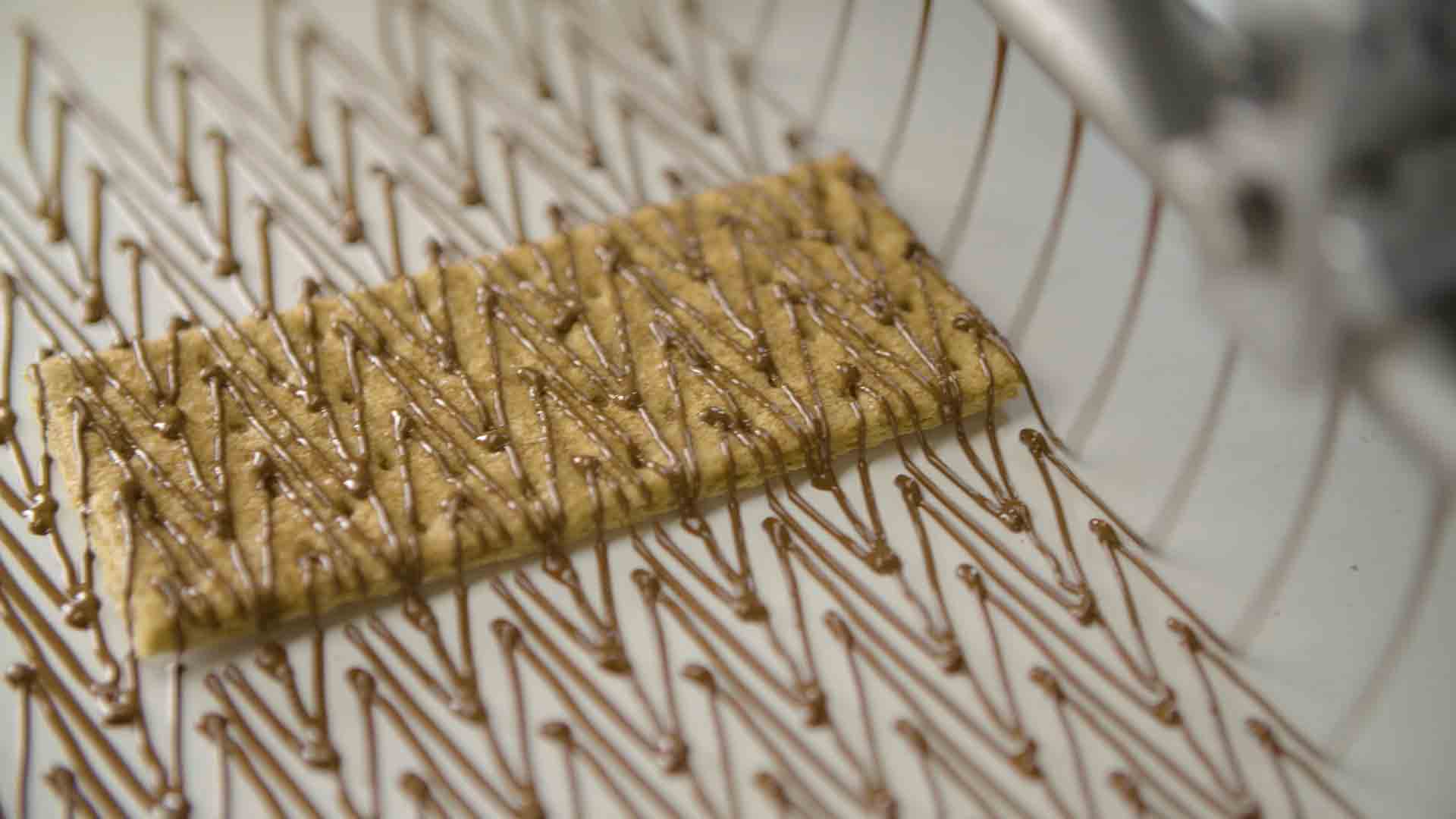

The confectionery model of the Woody Stringer places a string-type decoration on an array of baked goods or chocolates. This model is built for the confectionery user for whom ease of use and versatility are valued characteristics.

Designed to be easily installed and removed by hand, the Confectionery Stringer is designed for normal daily production but is robust enough to handle overtime duty when called upon. The standard design is with a strong, lightweight aluminium frame and stainless steel product areas. Compact, efficient, permanent magnet motors are used to keep the overall mass at a minimum.

As with all of our Woody Stringers, the basic model of this machine comes equipped to produce zigzag designs. Simple adjustments permit the user to make fast or slow, wide or narrow, thick or thin decorations. Each Stringer is equipped with our patented motor driven strainer, which cleans the chocolate before it reaches the nozzle tube ensuring consistent operation all day long.

Design upgrades of this Stringer can include the Single-Loop Attachment, allowing users to create loops, circles, slanted ovals and slanted zigzags. Also available is the Double-Loop Attachment, which allows an increased selection of decorative patterns including a figure eight (8) design.

The Confectionery Stringer can also be designed to make random patterns to simulate hand decorating, cross-hatching patterns and more.

Confectionery Stringer Quick Facts

- Available in 120V or 230V (50/60Hz) for easy plug and play operation

- Fractional horsepower motors for energy efficiency

- Simple installation and cleaning procedures

Additional Options

- Single-Loop Attachment

- Double-Loop Attachment

- Nozzle Heater

- Heated Enclosure

- Purging Nozzle Tube

- Washdown Construction

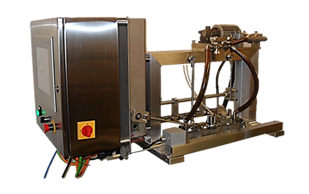

Designed with continuous operation in mind, the bakery model of the Woody Stringer is constructed to withstand hours upon hours of continuous service without the need to halt operations.

The bakery model differs from the confectionery model based on the typical inclusion of Heavy-Duty Construction. The Heavy-Duty Construction includes heavier rods, a larger frame and a stronger drive motor. Higher capacity product areas improve performance during high-level production sessions.

As with all of our Woody Stringers, the basic model of this machine comes equipped to produce zigzag designs. Simple adjustments permit the user to make fast or slow, wide or narrow, thick or thin decorations. Each Stringer is equipped with our patented motor driven strainer, which cleans the chocolate before it reaches the nozzle tube ensuring consistent operation all day long.

Design upgrades of this Stringer can include the Single-Loop Attachment, allowing users to create loops, circles, slanted ovals and slanted zigzags. Also available is the Double-Loop Attachment, which allows an increased selection of decorative patterns including a figure eight (8) design.

The Bakery Stringer can also be designed to make random patterns to simulate hand decorating, cross-hatching patterns and more.

Bakery StringerQuick Facts

- Available in 120V/230V single-phase or 240V/480V three-phase operation

- Fractional horsepower motors for energy efficiency

- Available with 56C face motor

- Simple installation and cleaning procedures

Additional Options

- Single-Loop Attachment

- Double-Loop Attachment

- Nozzle Heater

- Heated Enclosure

- Purging Nozzle Tube

- Washdown Construction

Our new Servo Stringer allows for users to change and save patterns with the touch of a button, instead of altering patterns using knobs and cranks.

The Servo Stringer is designed to comply with the latest FDA/GMA guidelines regarding cleanability and sanitary design of equipment. The standard machine has an aluminum frame and stainless steel product areas, but the entire machine could be stainless if desired.

This model encompasses several attributes within one machine. It can work at speeds exceeding 1,000 CPM, features Heavy-Duty and Washdown construction and can create patterns up to 4” wide.

The memory of the Servo Stringer allows the user to save hundreds of pattern settings for a later use. Switching back and forth between these settings is as simple as pressing a button. This feature is great for customer decorating multiple products.

At the present time the Servo Stringer is designed to make all of the standard patterns including zig zags, slanted zig zags, loops, ovals, figure-eights and cross-hatching. Different from the standard Stringers, this unit has the capability to have additional programming for the future. Based on some feedback from customers we are working on some enhancements to include additional components.

Quick Facts

- Available in 120V or 230V (50/60Hz) single phase for easy plug and play operation

- Durable Servo motors for maximum pattern adjustments

- Complies with all the latest FDA/GMA specifications for food safety

- Washdown construction

Additional Options

- Nozzle Heater

- Heated Enclosure

- Purging Nozzle Tube

The Woody Stringer can also be designed for all stainless steel construction. This construction option can be applied to either the Confectionery Stringer or the Bakery Stringer. In specifying stainless steel construction, all components of the Woody Stringer are made from grade 304 or better stainless steel.

All motors, controls and fittings on the stainless steel Stringer are designed for washdown operation. Because of the nature of the material, full stainless steel construction typically results in a machine that is much heavier than a typical Woody Stringer. Small Stringers can be removed by hand, but larger units are designed to remain in place.

As with all of our Woody Stringers, the basic model of this machine comes equipped to produce zigzag designs. Simple adjustments permit the user to make fast or slow, wide or narrow, thick or thin decorations. Each Stringer is equipped with our patented motor driven strainer, which cleans the chocolate before it reaches the nozzle tube ensuring consistent operation all day long.

Design upgrades of this Stringer can include the Single-Loop Attachment, allowing users to create loops, circles, slanted ovals and slanted zigzags. Also available is the Double-Loop Attachment, which allows an increased selection of decorative patterns including a figure eight (8) design.

The Bakery Stringer can also be designed to make random patterns to simulate hand decorating, cross-hatching patterns and more.

Stainless Stringer Quick Facts

- Suitable for either confectionery or bakery users

- Wash down motors and controls

- Simple installation and cleaning

Additional Options

- Single-Loop Attachment

- Double-Loop Attachment

- Nozzle Heater

- Heated Enclosure

- Purging Nozzle Tube

Two Color Stringers

We have built special Woody Stringers to decorate with two colors at the same time. These special Stringers have included versions with an interlaced pattern of two colors, random patterns of two colors and Stringers where ½ of the belt is decorated with one color and the other ½ of the belt is a different color. These Stringers are specially developed to meet the customer’s needs and we would be happy to discuss the possible options with you.

Long Stroke Stringers

The typical stroke of the Woody Stringer is variable from zero to about two inches (50mm). A special design of the Woody Stringer permits a longer stroke up to about four inches (100mm), while maintaining the available options of single loop and double loop patterns.

Exceptionally long strokes can also be made with the Woody Stringer. We have built machines capable of a twenty-four inch (24”) long stroke. This Stringer is suitable for certain customers, but there are some limitations.

Random Stringer

The Woody Random Stringer mimics the effects of hand decorating confectionery and bakery items. The Random Stringer can decorate truffles with a delicate thin string or a decadent cake with a heavy layer of chocolate.

High-Speed Stringer

The standard speed range of the Woody Stringer is 20 to 250 cycles per minute for the standard Stringer and up to 500 cycles per minute with heavy-duty construction. Special Stringers have been designed to handle speeds up to 1,000 cycles per minute.

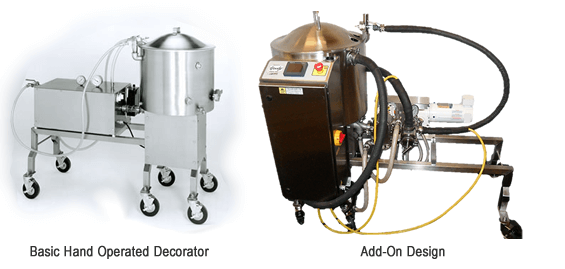

The Hand Operated Decorator is designed to replace the use of pastry bags or squeeze tubes when decorating with chocolate. The decorating material is pumped under controlled pressure to one or more operators and the only effort required by the operator is to gently squeeze and guide the handheld nozzle. The operator does not have to stop every few minutes to refill a pastry bag or bottle. Therefore, with the Hand Operated Decorator one operator can produce approximately twice as much with less effort.

The Woody Hand Operated Decorator uses standard decorating tubes, which are available with many different flutes. A box of various decorating tubes is included with the machine.

The basic machine is available as a self-contained unit and includes a cast iron pump with a pressure selector system, internal heating and control, pressure and temperature gauges, a sanitary stainless steel hood, double outlet adapter and valve, two high-pressure hoses and a box of 48 different decorating tubes.

Alternatively, the Woody Hand Operated Decorator can be provided as an add-on design. Typically this unit is attached to a supply kettle and pump assembly and uses the hot water from the supply kettle for warmth. The add-on unit disassembles easily for cleaning.

Basic Hand Operated Decorator Quick Facts

- Available in 120V or 230V (50/60Hz) for easy plug and play operation

- Fractional horsepower motors for energy efficiency

- Enough power to supply one or more operators

- Simple installation and use

Add-On Hand Operated Decorator Quick Facts

- Simple addition to Woody Kettle/Pump Assembly

- Water jacketed

- Easy to clean design

- Designed to supply more than one operator

Supply Kettles (tanks)

Compact stainless steel supply kettles are available for use with the Woody Stringer. Tank capacities start at 125 lbs. (56 Kg). All tanks include a slow moving agitator, electrically heated water jacket with digital temperature control, complete under frame with accommodation for our pump and casters (wheels) for easy mobility.

Pumps

Pumps are available in cast iron and stainless steel designs. All pumps include a variable speed motor, which is washdown rated when included with a stainless steel pump. The size and capacity of the pump depends on the customer’s requirements. All pumps are available with a water jacket.

Heated Hoses

The Stringer and Hand Operated Decorator can be equipped with heated hoses. The heated hoses are supplied with a separate digital temperature control. The heated hoses are typically used between the pump and the Stringer itself. A special silicone based heated hoses is used for the operator hose of the Hand Operated Decorator if ordered.

Conveyors

Normally the Woody Stringer is designed to fit the customer’s existing conveyor or fitted to the enrober. If required, we can provide a custom conveyor to accompany the Stringer.

Woody Decorators

Carefully crafted designs for innovative projects

Finance available on orders over £1,000

Start-up Businesses

Finance fromMedium Businesses

Finance fromLarge Businesses

Finance fromVantage House can help with your purchase through various payment options using Time Finance.

For an indication of deposit and monthly payment structure please click the Get a Quote button or phone our friendly team.

Please note other lenders are available.